How does this work?

BRIEF DESCRIPTION:

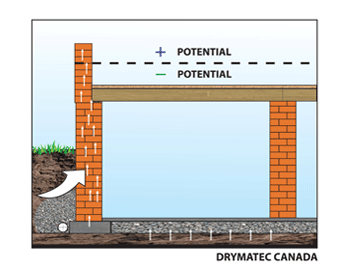

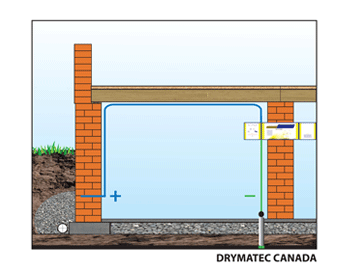

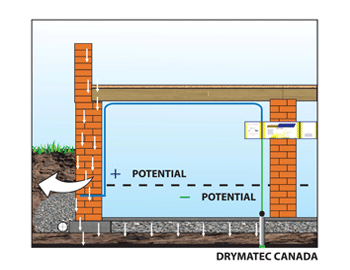

The DRYMATEC patented method is based on the electro-physical principle of displacing moisture from masonry and similar building foundation materials through electrical impulses.

Advantages of this method:

- One week after installation and operation the results can be measured with substantial reduction of moisture content.

- Installation in most cases is straight forward with minimal disruption or damage to existing building and finishes. The location of anode pins and main unit are designed based on initial no cost inspection and analysis with state of the art micro wave moisture detector and computer program. Care and consideration is given to existing finishes and routing of cables and firmly fixing anode pins. Century homes, high end finishes and historical buildings in most cases can be worked on with minimal detriment and disturbance.

- On the typical and average installation the Drymatec system is usually priced at about 50% less when compared to other methods.

- Installation is quick and typically takes one to two working days. Depending on existing finishes and the time required to protect existing the installation may take up to three or four working days.

- Exterior foundation walls ( field stone, clay/masonry brick, cement block, reinforced concrete) and concrete floor slab ( typical industry thickness) are dried and moisture content is verified with micro wave moisture analyzer.

- Average yearly electrical power consumption is about 5 KW.

- Standard 10 year warranty on main unit and installation is included. Purchase of extended warranty is available as a separate to the original purchase agreement.

- The Drymatec system is suitable for the following applications but not limited to, residential houses, century homes, historical buildings and churches, public buildings, prefabricated buildings, manufacturing and warehouse buildings , where moisture and water is a problem.

Basically how it works: